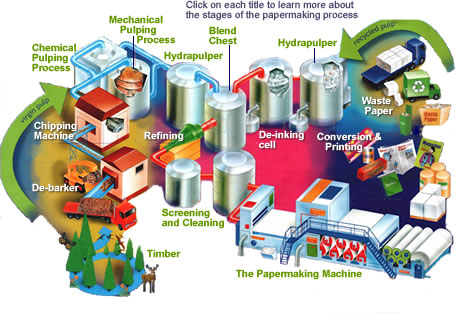

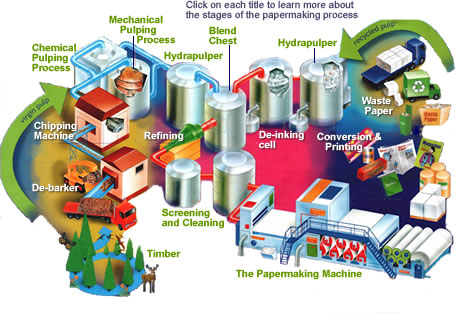

The Full paper making process

Timber

Timber used for papermaking comes from well managed forests where more trees are planted than harvested to ensure sustainable growth.

Papermakers usually use only the parts of the tree that other commercial industries don't want - such as saw mill waste and forest thinnings.

Go to publications for details of a Trees used for Papermaking Poster.

De-Barker

Bark is stripped from the logs by knife, drum, abrasion, or hydraulic barker. The stripped bark is then used for fuel or as soil enrichment.

Chipping Machine

Stripped logs are chipped into small pieces by knives mounted in massive steel wheels (used in chemical pulping process).

The chips pass through vibrating screens, whereby both undersized chips, dust etc and oversized chips are rejected.

Accepted chips are then stored in huge bins ready for the next process.

Chemical Pulping Process

Chips from the storage bins are fed into a digester to which chemicals have been added. The woodchips are then 'cooked' to remove lignin. Lignin is the binding material which holds the cellulose fibres together.

The chips are 'cooked' by heat and pressure in caustic soda and sulphur.

The chemical process is energy self-sufficient as nearly all by-products can be used to fire the pulp mill power plant. The chemical pulping process produces lower fibre yield than mechanical pulping, typically 50-60%.

Mechanical Pulping Process

Mechanical pulp yields over 90% of the wood as fiber is produced by forcing debarked logs, about two meters long, and hot water between enormous rotating steel discs with teeth that literally tear the wood apart. Alternatively, logs can be pressed against grindstones which is why this process is also known as ground wood pulp.

Trees contain up to 30% lignin, a material which is sensitive to light and degrades, and turns brown in sunlight, which explains why papers made from mechanical pulp will discolor. An example of this is newsprint. Newsprint is designed to have a short life span, and if left for a long period of time will lose its whiteness and strength. The special advantages of mechanical pulp are that it makes the paper opaque and bulky.

Hydrapulper

When the bales of wood pulp or waste paper arrive at the paper mill they are loaded onto a conveyor and passed into a circular tank containing water. This has a very powerful agitator at the bottom which breaks up the bales into small pieces.

When the bales of wood pulp or waste paper arrive at the paper mill they are loaded onto a conveyor and passed into a circular tank containing water. This has a very powerful agitator at the bottom which breaks up the bales into small pieces.

The pulp mass created begins to look like thick porridge. This machine is known as a Hydrapulper. It operates automatically and when the disintegrating process is complete it discharges the pulp into large storage tanks.

Hydrapulpers used mainly for handling waste paper are fitted with special devices for removing unwanted contraries such as wire, plastic, paper clips, staples etc.

Blend Chest

The stock passes to a blend chest where numerous chemicals can be added to obtain the required characteristics to the finished paper. Dyes are also added, as necessary, to color the paper. Dyes fix themselves to the cellulose fibers and are fast to light and water.

Each grade of paper and board requires a very accurate blend of pulps and additives and the properties of the paper are continually monitored by computers during manufacture.

Waste Paper

Waste paper is collected from Waste Paper Banks and Commercial collections. When you deposit your used papers into a waste paper bank, you are sorting the paper into grades before the merchant collects it. This is why you can only put certain papers into a particular bank.

Many offices have in place an office recycling scheme. Again the waste paper is usually segregated ready to be collected.

Waste paper currently represents 67% of the raw material used in the UK to make paper and board.

The waste paper merchant collects the used paper which is then sorted by hand into different grades. Paper not suitable for recycling is removed.

The waste paper merchant will then bale the waste paper ready to be taken to the paper mill

De-inking

Before printed paper, such as office waste and newspapers, can be recycled the ink needs to be removed, otherwise it will be dispersed into the pulp and a dull grey paper would result.

There are two main processes for de-inking waste paper - these are known as washing and flotation.

Washing

The waste paper is placed into a pulper with large quantities of water and broken down into a slurry. Contraries -such as staples - are removed using centrifugal screens. Most of the water containing the dispersed ink is drained through slots or screens that allow the dispersed ink particles through, without taking the pulp. Adhesive particles, known as 'stickies' are removed by fine screening.

Flotation

Again the waste is made into a slurry and contaminants removed. Special surfactant chemicals are added which makes a sticky froth on the top of the pulp.

Air bubbles are blown through the pulp and these carry the inks to the surface. As the bubbles reach the top a foam layer is formed that traps the ink. The foam must be removed before the bubbles break or the ink will go back into the pulp. Because the ink is removed from the flotation machine in a concentrated form, the flotation system does not require a large water treatment plant.

Refining

This is where the cellulose fibers pass through a refining process which is vital in the art of papermaking. Before refining, the fibers are stiff, inflexible and form few bonds. The stock is pumped through a conicle machine which consists of a series of revolving discs. The violent abrasive and bruising action has the effect of cutting, opening up and declustering the fibers and making the ends divide. This is called fibrillation. In this state, the fibers are pliable and have greater surface area, which significantly improves the fiber bonding. The properties of the paper are directly related to the refining process. Refining used to be called beating.

Screening and Cleaning

Pulps contain undesirable fibrous and non-fibrous materials, which should be removed before the pulp is made into paper or board.

Cleaning involves removing small particles of dirt and grit using rotating screens and centrifugal cleaners.

Papermaking Machine

The Paper Machine is a very large piece of machinery. A typical machine is about the length of two football pitches and around 4 metres wide. It can run up to speeds of 2000 m per minute - or 60 miles per hour! The machine itself consists of 7 distinct sections. The flow box, wire, press section, drier section, size press, calendar and reeling up.

The first section of the machine is called the 'Wet End'. This is where the diluted stock first comes into contact with the paper machine. It is poured onto the machine by the flow box which is a collecting box for the dilute paper stock. A narrow apperture running across the width of the box allows the stock to flow onto the wire with the fibres distributed evenly over the whole width of the paper machine.

The machine is operated by computer control. The computer will monitor the paper for moisture content, weight etc and computer screens will show pictures of the process and should any adjustments need to be made, an alarm will sound.

Conversion and Printing

Once the paper is made, a great deal of it is converted into a product. Converters specialize in transforming reels and sheets of paper and board into a vast array of finished products for distribution such as boxes, cartons and stationery. Converters sell their products to the public or to other manufacturers.

Not all paper and board is processed by converters. Some papermakers do their own converting, for example, the manufacturers of soft tissues market their own products and sell directly to the public.

The printing industry converts large quantities of paper and board, much of which reaches the customer as newspapers, magazines or books.